Analysis Of Synchronous Belt Tooth Failure

When the synchronous belt fails, few people carefully check the synchronous pulley, and it is usually thought that the synchronous belt itself is the problem.

When the synchronous belt run on a synchronous pulley of questionable size, belt tooth side will show a high degree of wear, and the canvas on the side of the synchronous belt will become fuzzy fluff or flake.

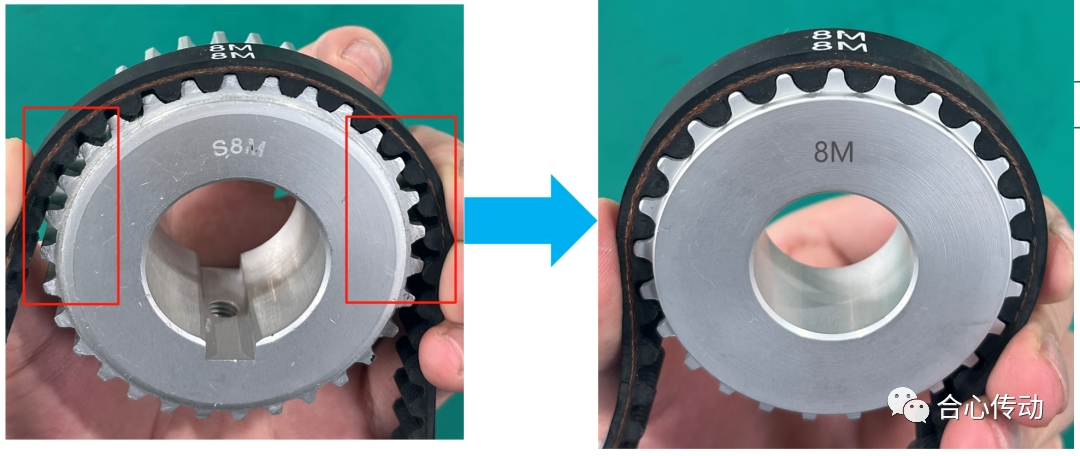

As shown in the figure, HTD8m rubber synchronous belt selected by the customer is used on the synchronous pulley tooth of S8M. At the beginning, the tooth shape is engaged, but at the back, the tooth shape has been disjointed, resulting in skipping teeth, resulting in belt wear. Replace the corresponding HTD8m synchronous pulley.

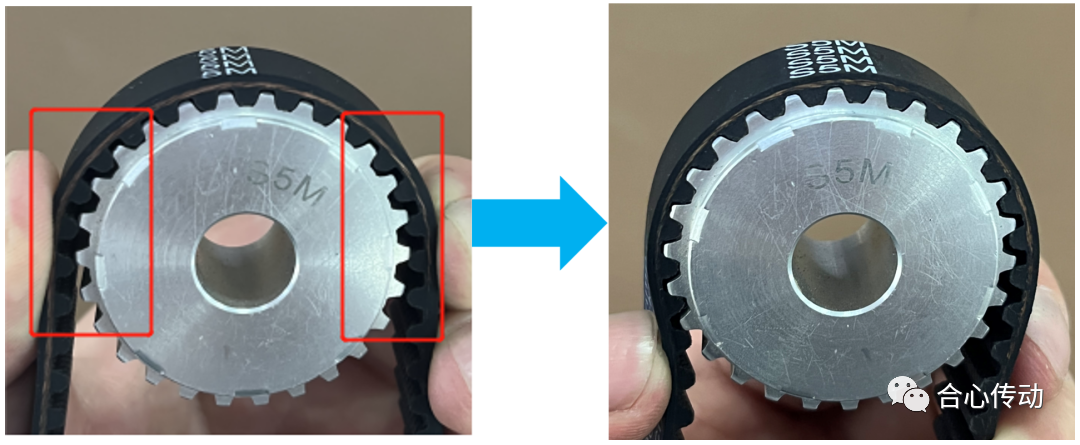

Similarly: the S5M synchronous pulley using HTD5M rubber synchronous belt will lead to the tooth shape can not be perfectly engaged, and finally lead to belt wear, using the corresponding S5M rubber synchronous belt problem to solve.

Highlight: Analysis Of Synchronous Belt Tooth Failure

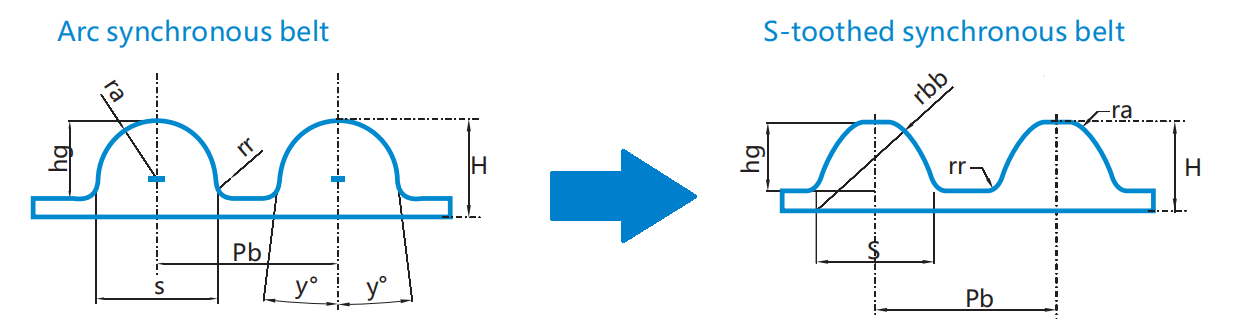

--Different tooth types are never used together

In particular, the □M series and the S□M series cannot be used together

S□M series, S2M/S3M/S5M/S8M are semi-circular arc teeth

□M series, 2M/3M/5M/8M are full arc teeth

(□M, sometimes called HTD□M or H□M)

The synchronous belt with the same tooth type and the synchronous pulley should be used together, That is the analysis Of Synchronous Belt Tooth Failure - why is the belt cracked, aging, and even broken?

We can check the synchronous pulley from the following aspects:

The mouth of a small threaded hole, if the burr is sharp, will damage the belt product, which is the fatal cause of shortening the life of the belt--analysis Of Synchronous Belt Tooth Failure